One Option for Altering the Availability of Manufacturing Capacity Is

One option for altering the availability of manufacturing capacity is Apricing. Flexing capacity to meet demand.

Solved Mc Qu 42 One Option For Altering The Availability Chegg Com

A second strategic approach to matching demand and capacity focuses on adjusting or flexing capacity.

. Companies often use this capacity strategy as it allows a company to ramp up production at a time when the demands on the manufacturing plant are not so great. One such option is. One option for altering the availability of manufacturing capacity is.

None of the above. One option for altering the availability of manufacturing capacity is. One option for altering the availability of manufacturing capacity is.

One option for altering the availability of capacity is. One option for altering the availability of manufacturing capacity is. Multiple Choice pricing back orders.

Use of overtime can help in altering the availability of capacity. Use of overtime or slack time B. Which of the following is not a basic option for altering the availability of capacity in a service environment.

Target Capacity is the amount you will produce when you reach your OEE target reducing Equipment Losses and schedule more production time reducing Schedule Losses. None of the above apply to manufacturing capacity AACSB. None of the above apply to manufacturing capacity.

MAINTAIN PRODUCTION CYCLES. Aggregate planning is the procedure of creating a production schedule for a given period. Seasonal demand fluctuations can be planned for using historical data and production line capacity can be easily managed to handle the rise in demand.

The fundamental idea here is to adjust stretch and align capacity to match customer demand. Capacity planning lets businesses know how and when to scale identify bottlenecks create better design capacity and mitigate risk within a planned period of time. Manufacturers can maintain proper production levels as per expected business requirements and cycles with a good Capacity Planning Strategy.

Aggregate planning covers elements like human resources raw materials financial planning operations. Capacity management is the management of the limits of an organizations resources such as labor force manufacturing and office space and inventory. One option for altering the availability of capacity is.

Using combination of inventories overtime part time and back orders In order to use the level capacity strategy variations in demand are met by. Remember though many manufacturers can. Capacity and inventories d.

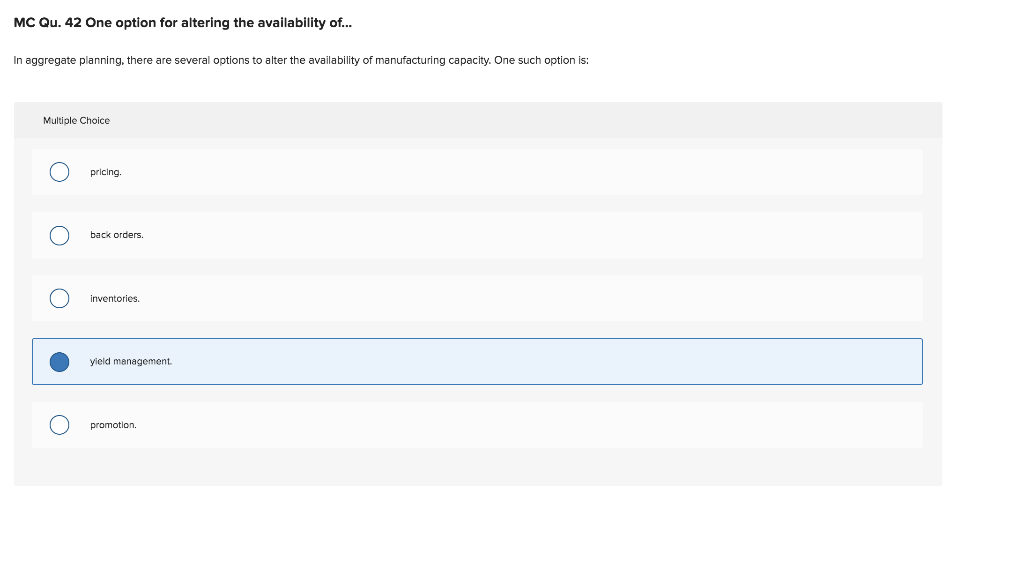

As the name suggests the lead capacity strategy adds capacity before the demand actually occurs. In aggregate planning there are several options to alter the availa bility of manufacturing capacity. Lead Capacity Strategy.

If the factory is producing only one style Shirt of SAM 25 minutes and used all 200 machines daily production capacity at 50. Demand and costs c. One strategic approach to matching capacity and demand for a service provider focuses on reducing demand during times when customer demand is at its peak for service.

One of the easiest ways to measure capacity is to simply use the total production quantity for a given time period. Aggregate planners attempt to balance. None of the above.

It helps to calculate the production capacity based on the requirement of the product against. Use of overtime or slack time B. All of these are basic capacity options.

One option for altering the availability of capacity is. It is important to know about aggregate planning while creating production schedule. One option for altering the availability of manufacturing capacity is.

Demand and inventories b. One option for altering the availability of capacity is. It starts after listing out all the requirements that are crucial for uninterrupted production.

One option for altering the availability of capacity is. Asked Aug 19 2019 in Sociology by shiva. Asked Aug 28 2019 in Business by Kitcat.

20006050 25100 Pieces. Use of overtime or slack time B. Total factory capacity per day is 2000 hours 200 machines 10 hours.

Either by altering the availability of the neurotransmitter in the synapse or by. Strategies that make use of qualities. Balance the load at Work Center.

Use of overtime or slack time. During periods of peak demand the organization seeks to stretch or expand its capacity as much as possible. Capacity planning is a type of production planning that involves determining production capacity and workforce needs to make sure your supply chain is equipped to meet demand.

43 Increase demand to match. None of the above. Current Capacity is the amount you can produce using your equipment as is at its current effectiveness and within your current production schedule.

The main function of capacity planning is to check the load at Work Center and do the capacity leveling ie. For example if your plant can produce an average of 20000 gizmos per week then your total capacity is 20000 gizmos per week. Strategies that alter capacity to match demand are known as Reactive Strategy.

Ause of overtime or slack time Bpricing Cpromotion Dbackorders Enone of the above Overtime or slack time alters the availability of capacity. One option for altering the availability of capacity is. Drugs can affect neurotransmitter systems in two main ways.

Capacity and costs e.

Aggregate Planning Is Capacity Planning For A The Long Range B The Intermediate Course Hero

One Option For Altering The Availability Of Manufacturing Capacity Is A Pricing Course Hero

One Option For Altering The Availability Of Manufacturing Capacity Is A Pricing Course Hero

Comments

Post a Comment